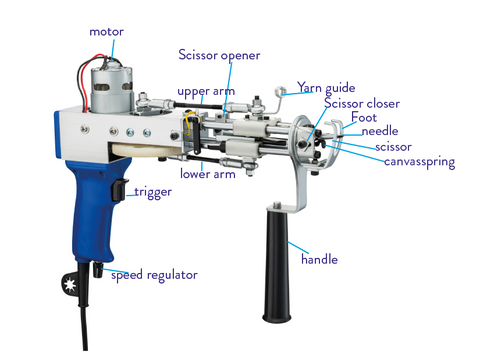

The parts of your machine

AK-I Machine specifications

The AC/DC adapter included with the machine can handle up to 240 volts AC (alternating current). Household electrical power is commonly AC. It converts up to 240 volts AC power to 30 volts DC (direct current), which is needed for your tufting gun. It is the type of adapter found on many devices we use everyday like laptops. The plug included is for the EU, might you need another plug, then it will work with a simple plug (travel) adapter too.

PILE HEIGHT (7-18mm, adjustable)

SPEED RANGE 5.45 stitches/sec

WEIGHT1.4 kg

UNIVERSAL VOLTAGE 100 - 240 V , 50 - 60 HZ

Changing the height of the pile

Setting the AK-I on max pileheight

In this use case we work from the default settings of you machine.

- The first tep is to shorten the upper arm to 53 mm.

- The lower arm stays the same. And so, the position of the scissor opener stays the same also

- The second step is to move the foot to the position where it lines out with the bottom of the needle hole. Which means it should be about 31 mm, this is as low as it can be.

- After that, make an adjustment to the canvasspring, it should only be sticking out appr. 6 mm from the foot. So loosen the small bolt, tap it down and fasten at 6 mm.

- The final step is to change the point where the scissor closes. To do this, loosen the screw on the scissor closer. Move the wheel to the point where the scissor is al the way in (where it opens) and continue to rotate it to the point where it points out. Now push the scissor closer in while observing the scissors. At on point it will start closing. This is the point where it needs to be fast.

Finetuning

Sometime your machines scissors need some finetuning so that is cuts correctly. These adjustments are similar to the finetuning after changing the pile height. It is really easy to get it right.

Scissors closing

Scissors opening

Changing the size of the needle eye

Troubleshooting

Running check

After making any changes to the pileheight or after changing the scissors, always do this running check, especially if you notice the machine is not working correctly.

If you notice the distance between the scissors and the needle is too big when in uniform height, you can decrease the distance by pushing a piece of paper under the scissors, or manually bending the scissors a little further.

Connecting the motor to the gear.

Sometimes the motor gets slightly dislocated, for example because of the packing. This is an easy fix. You need to make sure that the wheel of the motor is correctly touching the wheel of the white gear. Unscrew the 4 screws that hold the motor in position. Bring the motor in the correct position and tighten the screws.

Maintenance

Maintaining the machine is easy. Remember to unplug the machine when doing so.

- Add a drop of sewing machine oil (or any lubricating that is color and odorless, you dont want stains on your rug) to each linear bearing, at least every week to keep the machine running smoothly. For longer tufting sessions it wouldn't hurt to oil more often.

- The cut pile machine should have a drop of oil added to the scissor joint monthly (where the two sides of the scissor cross)

- Other metal parts that move should also be oiled monthly (where the arms connect to the machine for example).

- Remove loose yarn strands and dust from moving parts with a brush or blow some compressed air to clean the machine.

- Never store or rest your machine on the side with the main power switch. It is delicate and can break.

If you have any issues with your machine please send an email to info@tuftingshop.com where someone will help you, and dont forget to look al our tufting wiki for common problems and solutions.

Factory setting

The parts of the machine need to be in perfect harmony to operate as they should. The movements of the upper arm and bottom are should be in sync. After making any changes to the machine such as the pile height, the settings can be misaligned causing the machine not to work properly.

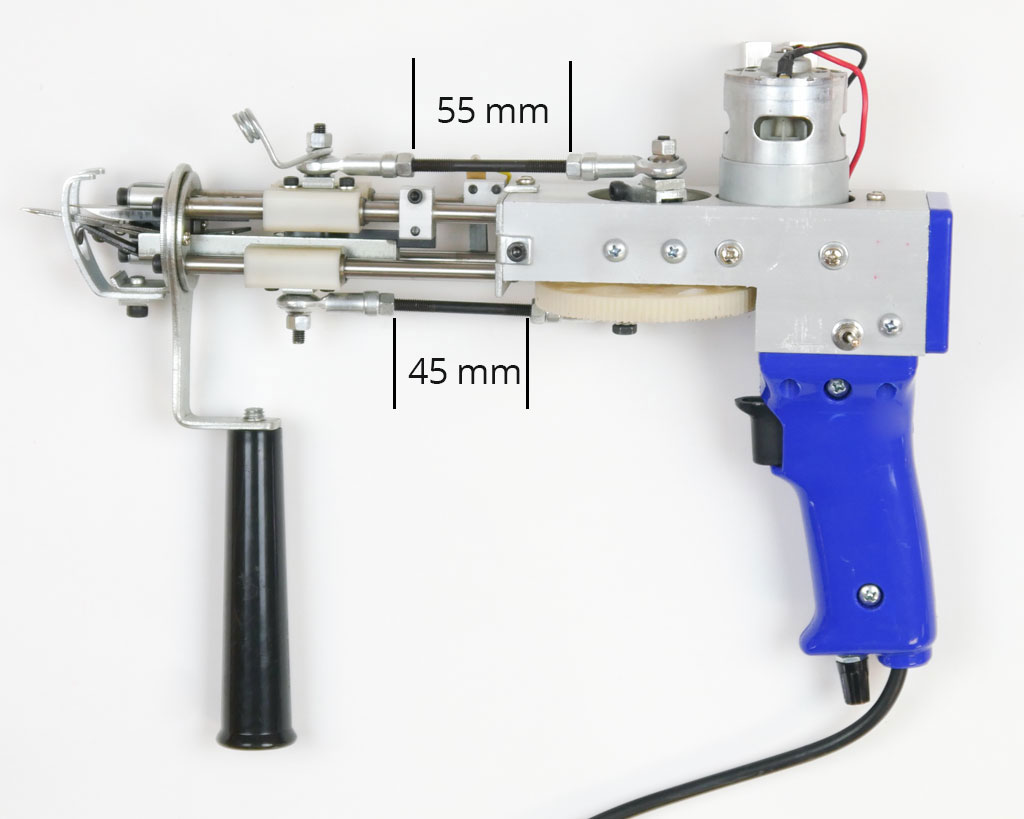

See the image below from tuft the world to find the factory setting. of the arms.

for all other settings, please refer to the above information about the scissors and foot.